Descriptio:

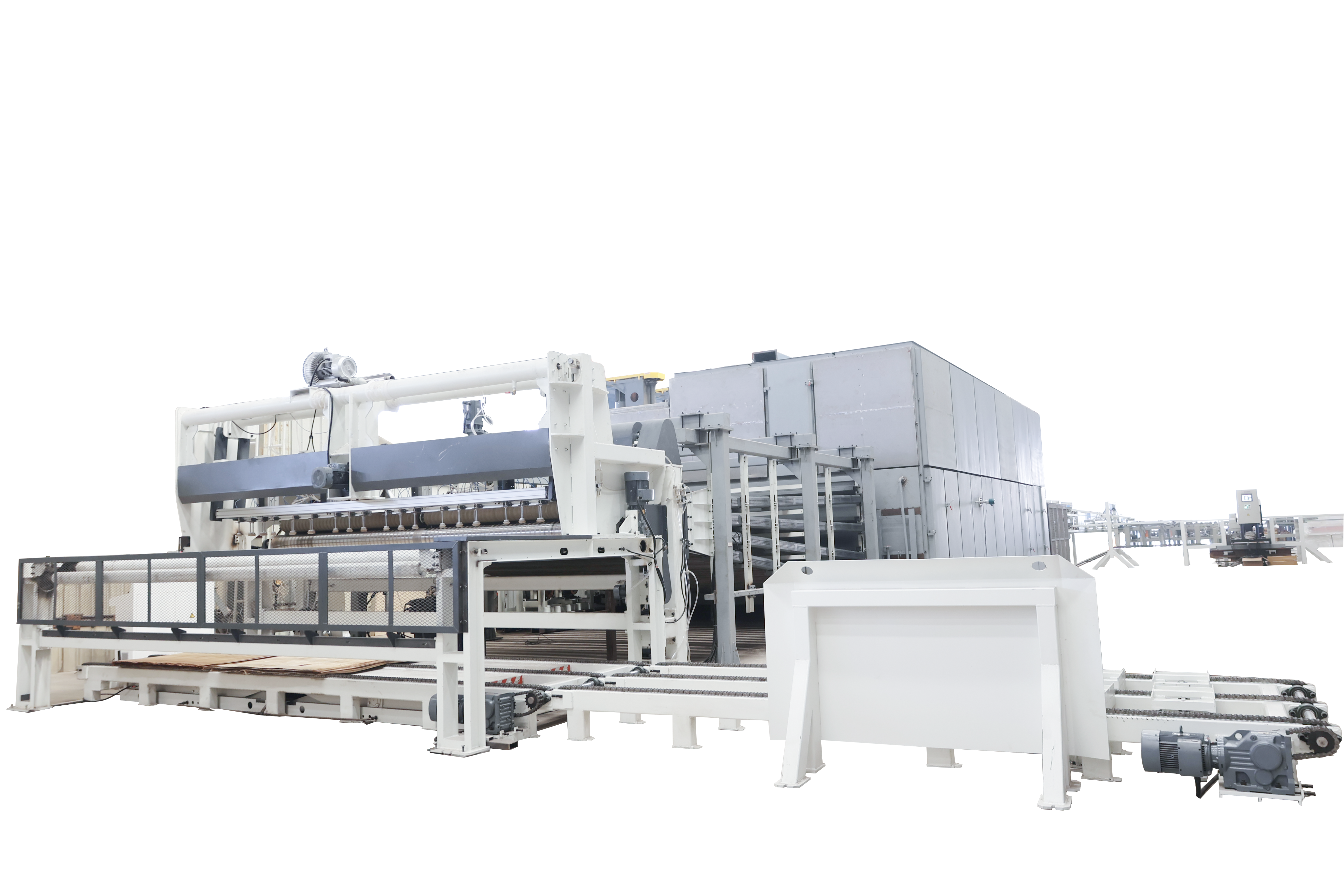

Folii siccatio est una ex clavis stage in folii productione. Principale scopus processus siccandi est producere altam qualitatem siccum folium cum maxima efficentia possibilia. Hoc fit per utendum calido et umido aere intra siccatorem ad tollendum humiditatem ab folio et reducendum humiditatis contentum ad optimum level.

Possumus praebere varietatem differentium series folii siccationis lineas secundum clientis optio, et possunt dividere siccum folium in differentes folii species per comparationem cum humiditate analyzatoribus, qualitas analyzatoribus et aliis apparatus. Est utilis pro plywood vel LVL productione.

Praecipua lineamenta:

*Uniformis humiditas contentum folii post siccationem

*Unicum jet box structura, quod potest effectiviter evitare folii obstructionem

*Efficientia ventillatoris centrifugalis et radiatricis caloris ad altam productionem vernicis

*Efficientia isolationum efficaciter minuit consumptionem energiae

*Omnes ventilatores sunt in eadem parte pro facili conservatione

*Parcendo operibus, tota linea productionis solum requirit unum vel duos operarios ad operationem

*Systema immissionis superpositionis (optionale), quod potest incrementum capacitatis productionis usque ad 10% afferre

*Systema controlis temperaturae et umiditatis aeris (optionale), sponte regulat temperaturam et umiditatem in camera sicandi, servando usque ad 20% consumptionis energiae per metrum cubicum laminarum productarum

*Systema extinctionis ignis automaticum (optionale)

Specificationes:

| Exemplum | HG132\/3000-8+1 | HG182\/3000-8+1 | HG192\/3000-8+1 | HG133\/3000-8+1 | HG183\/3000-8+1 | HG193\/3000A-8+1 | HG193\/3000B-8+1 | HG134\/3000-8+1 | HG184\/3000-8+1 | HG194\/3000-8+1 | HG134\/5000-6+1 | HG134\/5900-6+1 | HG134\/6300-6+1 | |

| Typus | - | 2 Rotatores | 2 Retia | Rete&Rotulus | iII scutulis | 3 Rete | 1 Rete&2 Rotuli | 2 Rete&1 Rotuli | 4 Rotatores | 4 Retia | 2 Retia&2 Rotuli | Latus 4 Rotatores | Latus 4 Rotatores | Latus 4 Rotatores |

| Largitudo operativa | mm | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 5000 | 5900 | 6300 |

| Numerus pontis | - | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 |

| Longitudo sectionis calefactionis | mm | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 16100 | 12100 | 12100 | 12100 |

| Longitudo sectionis refrigerationis | mm | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 |

| Potentia exsiccandi | m³/h | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 6.5 | 7.5 | 8.5 |

| Consumptio vaporis | kg/h | 1780 | 1780 | 1780 | 2580 | 2580 | 2580 | 2580 | 3380 | 3380 | 3380 | 5040 | 5460 | 6000 |

| Motus totus | kw | 81.2 | 85.5 | 80.7 | 116.7 | 120.7 | 116.7 | 120.7 | 141.2 | 160.2 | 156.2 | 146.2 | 257.2 | 257.2 |

| Motor transmissionis | kw | 11+2.2=13.2 | 7.5*2+2.2=17.5 | 11+7.5+2.2=20.7 | 11+7.5+2.2=20.7 | 7.5*3+2.2=24.7 | 7.5+11+2.2=20.7 | 7.5*3+2.2=24.7 | 11*2+2.2=13.2 | 7.5*4+2.2=32.2 | 7.5*2+11+2.2=28.2 | 11*2+2.2=24.2 | 11*2+2.2=24.2 | 11*2+2.2=24.2 |

| Calefactor motor | kw | 7.5*8 | 7.5*8 | 7.5*8 | 11*8 | 11*8 | 11*8 | 11*8 | 15*8 | 15*8 | 15*8 | 18.5*6 | 37*6 | 37*6 |

| Refrigerationem motricium | kw | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4*2 | 4.2 | 4*2 | 4*2 | 5.5*2 | 15*2 | 15*2 |

| Celeritas tradenda | m/min | 0-15 | 0-25 | 0-25/0-15 | 0-15 | 0-25 | 0-25/0-15 | 0-25/0-15 | 0-15 | 0-25 | 0-25/0-15 | 0-15 | 0-15 | 0-15 |

| Dimensio totalis | mm | 29100*5260*3680 | 29600*5260*3700 | 38195*5260*3730 | 29100*5260*4180 | 32600*5260*4900 | 38195*5260*4230 | 38195*5260*4430 | 29100*5260*4680 | 32600*5260*5170 | 38195*5260*4930 | 25100*7060*4800 | 25100*8160*4800 | 25100*8560*4800 |

| Pondus | kG | 45000 | 42000 | 43500 | 49000 | 46000 | 47500 | 47000 | 56000 | 52000 | 59000 | 75000 | 89000 | 95000 |

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

BN

BN

LO

LO

LA

LA

KK

KK

UZ

UZ