Wood is a great material we used in variety of different things. Chairs we sit on, the tables eat at and even in houses they live! Wood is ubiquitous, and it plays a very important role in our routine activities. To get all of these items made out of wood, we have a special process that needs to be adhered. A large amount of the process is called as veneer drying line. This machine is very important in the wood industry, as it makes sure that your wooden elements are dry and ready for use which building or creating something new.

As humans, we cut down trees to turn them into various wood products but the timber which our ancient predecessors would consume is not raw… They are wet every day and must be dried (11). The first and perhaps most important is drying the wood, improperly dried oak can be fragile and easily break. This is where veneer dry lines become involved. In a special way, these lines dry the wood to become stable and have enough strength for use as furniture, flooring or another wooden product.

The importance of veneer drying lines in the wood industry The first is that it allow the wood to dry much faster than if we were to do this by hand or use other alternatives. Thus, more wood can be dried fast and this helps the wooden industry to produce as well as sell their products faster. Moreover, drying lines for veneer ensure an even moisture removal. This is crucial, because if the wood dries quicker in one end to a different it may give you issues. When wood is not properly dried, it will often have cracks or warps that make the piece unusable for building and crafting.

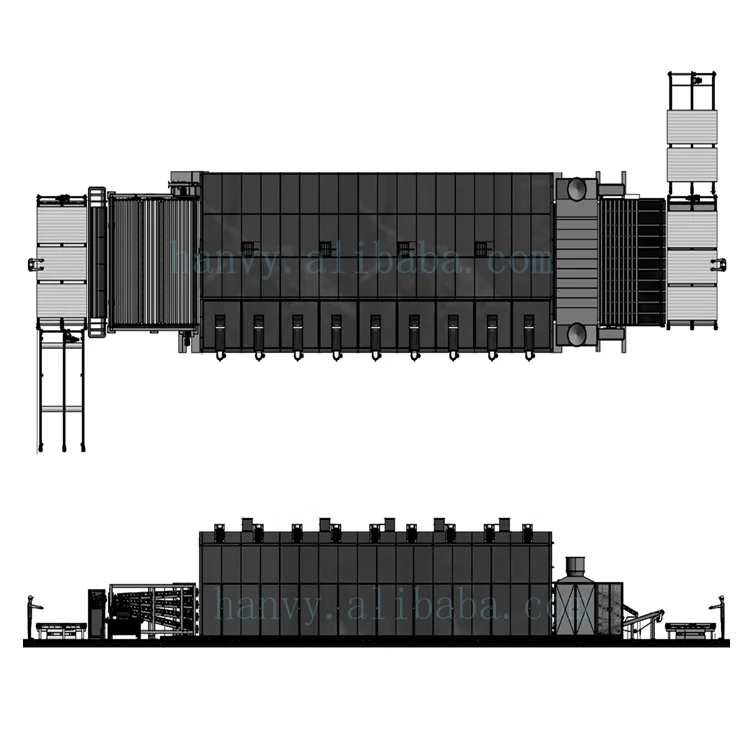

Many different components must work in tandem to allow for proper veneer drying with a pneumatic bypass. It has a core element which is called the conveyor. It is a moving belt that conveys the wood as it dries. It also contains a heating system that heats up the wood to aid drying. WOOD WOOD that the wood is absolutely dry, should be cooled down before it can be used Being cooled off enough for use is where the cooling system takes part. This is all controlled from a neat little control panel to help workers keep an eye on things. It makes sure all veneer drying line part work well and the wood is dried at suitable degree.

There are truly awesome breakthroughs in which veneer drying lines are revolutionizing the wood industry. These lines make the wood dry faster and hence help in processing more wood at a time which results into saving much industry area. This turbo speed is great for businesses because it can be used to sell more products in the fastest time possible, which of course,= meaning make money. Furthermore, as opposed to air-drying the same commodity worldwide does not one of drying strains for a longer time frame compared and circulation that it will lead to significantly stronger wood. This will be a significant benefit for their customers who purchase the wood, as it means receiving products that simply last longer and perform better.

Wood processing companies really do appreciate a good veneer drying line. They want these businesses to make more things and pay them a bunch of money. This will allow you to produce more products and sell them in a much faster time. This is great for the wood industry because it means you can save a lot of money. Additionally, by drying lines the wood is raised to higher quality which means that products made from it are stronger and have a longer lifespan. As such customers are more likely to be willing to pay a higher price point for these items, which of course help boost margins for the companies selling them.