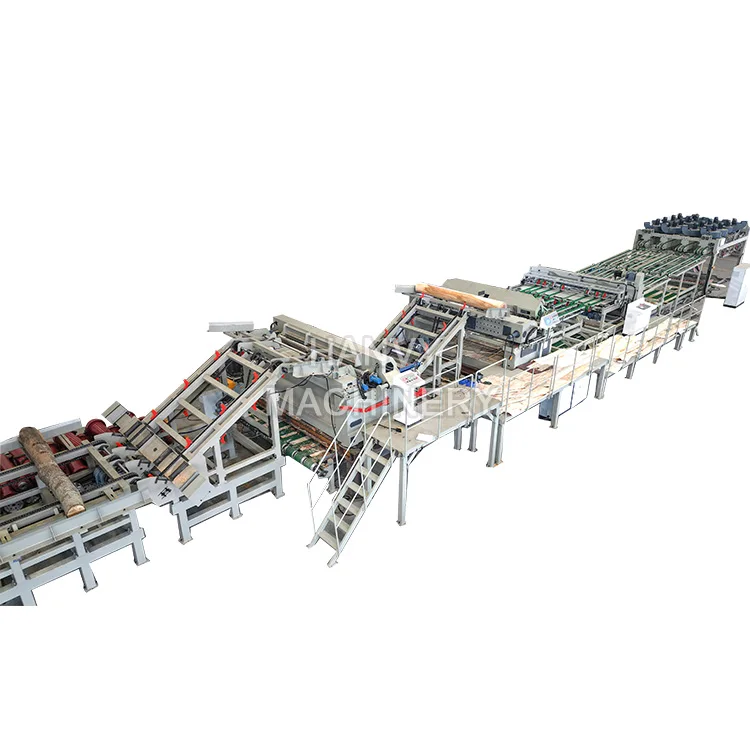

Veneer and plywood are hard to cut, splinter too easily if you do not have the right tools. However, for us woodworkers, today it has never been simpler to build something with modern Machines. This means that you will get several advantages in all your projects, for this we need to use our plywood machine and help the cutting of veneer be as fast and effective as possible. And it helps you with construction, because then there´s more to build — and less feature-fitting.

Going for the best veneer and plywood machine is a good opportunity to make your woodwork of high quality. We specialize in producing veneer and plywood at the highest level. This also means that all of your hard work will be beautiful and durable. Using our machine you would be able to create your very own amazing and diverse wood products range that will drive the customers crazy. This can lead to your business, expanding and keeping people happy with what you are serving them.

Veneer is utilized for the best to refurbish machines with and also keep up an all around loaded stock of plywood at our in house workshop. These are machines that are built to last, and they will do your precision cutting work without any hitches. This is very important because it will provide good results in your woodworking plans. And, if the machine you are using does not cut through cleanly then it just ends up being very expensive as you will be binning Paper and other products. The Tacklife PTSG1A is here to stay but not really at The Bottom of the line, folks — with a respectable 2.5 hp induction motor doing most heavy lifting this modestly placed cabinet saw does has what it needs for anyone looking to move up out into amateur-pro level unwanted category; Otheralternative mascotted like Sawstop on other side can now even stand-up without way more bells-and-whistles thanks beeing blessed by simples solid designs instead… So better shell for $600 price tag feels right mix between some-to-mass grade jobs!

Sometimes it might be a challenge to find the specific sizing of veneer — especially when you want an action project. But we use plywood machine only for one part that is focused on the primary custom sized boards as a demand of our customers. And these saws also do linear slitting for tasks such as slicing very thin veneers or cutting thick-based stock to size. Reply This application allows you to do pretty much any project not having to waste your time looking for veneer the fit into place perfectly. That gives you plenty the flexibility to visualize and try new thoughts on your woodcraft.

Essential to enabling us as developers, if we want that kind of craftsmanship is the tools. The veneer machine and plywood machines are made in such a manner that you can achieve great finishes from your side. This makes your project professional in appearance and this does a very good impression on the client. Take all of that chance out and instead, trust in our machine to go ALL the time EACH AND EVERY PERFECT FINISH. That way, with good eye for details your woodworking projects can certainly be viewed a little highlight and variety.