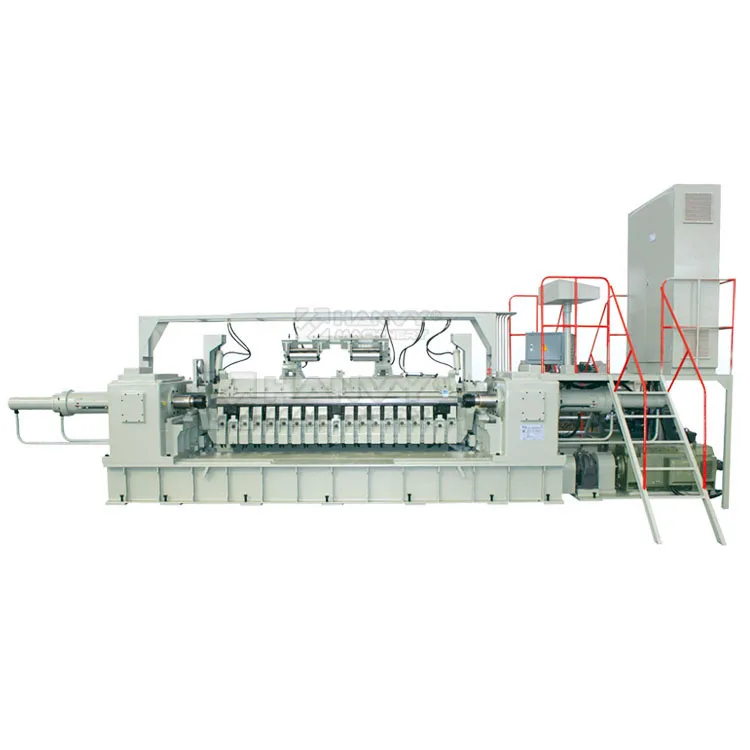

Have you ever noticed the sheen and smoothness of a furniture piece made out of wood? Veneer- this is the pretty shiny surface Veneer: A thin layer of wood that is applied to a stronger base material like plywood or MDF (Medium-Density Fiberboard) Veneer is used by people to make all kinds of furniture that also includes other types like cabinets, and even musical instruments such as pianos or guitars. In order to peel the veneer from a log needs specific rack-like machine – lathe (Fig. 1). Currently, the job has been replaced by workers of a new type with much faster and easier terminators — spindle veneer peeling machine.

A lathe is a machine which rotates an object about its axis as it cuts away excess material. The older lathe is a mount at the ends on piers that spin around, with log being held in place by spindle. But, occasionally this spindle may start malfunctioning and cause lumps or bruises on the wood. After that it passes to rollers and tapes instead of a spindle on the log, this way these type of problems are escaped. It has revolutionizes the way we produce veneer and makes it more efficient, reliable.

The spindless veneer peeling lathe has undoubtedly revolutionized how the industry produces great quality and highly sustainable Veneers. Not only was the older lathe slower but it also cut less precise veneer. It also made more defects in the kind of veneer it produced, so lower quality. On the other hand, better and more accurate than spindle shyamuk industries peel off Layer with out shak — bing lath. Manufacturers can produce a greater amount of veneer with higher quality in less time. This means, today less valuable wood is wasted in the production process.

The spindless wheels new technology to create large peeled veneers as opposed to longs slices that are later cut by a saw. This makes the veneered surface stronger and guarantees a uniform thickness for every piece of veneer. This continuous method of peeling the veneer also saves a great deal on time and on smaller parts that must be glued together. Since the veneer has fewer joints, which are where peeling and splitting can be a problem as time goes on, it will last longer both in its functionality and visually.

The spindless lathe incorporated a number of improvements that have yielded in much greater veneering capacity. This old lathe was very prone to off-center turning (hence the crude chuck) and made many mistakes resulting in huge piles of scrap wood. The spindles lathe, on the other hand, makes more precise and consistent veneer so that fewer forests are devastated in the manufacturing process. Also, this lathe is flexible to operate in trimming veneer from logs of come sizes and shapes. Aside from this, the manufacturers will have more freedom and can make over all better use of that tree resulting in less waste.

Another great benefit to the new and improved spindless lathe is that it makes use much safer than old design. The lathe processes are traditional and required a manual force which is hazardous for labours. It also has automatic spindless lathe-control to ensure the safety of human beings who use it. Additionally, it calls for a lot less upkeep than the old lathe which makes it simpler to run and keep in good working condition longer. In the end, this lathe cutting device has opened doors for making veneer safer and faster.