Do you like furniture? Did you ever wondered how piles of wood are converted to such nice chairs or tables? It's pretty fascinating! A key piece of equipment in this process is a single spindle veneer peeling lathe. A crane loads large logs into a machine that peels off layers of wood, leaving sheets as thin and pliable as paper. This article goes over what is a single spindle veneer peeling lathe, how does it work and its pros and cons as well as some safety tips on using the machine. So, in the end you are going to learn about a lot of machines that peel veneer and help make some great furniture!

Single Spindle Veneer Peeling LatheA single spindle veneer peeling lathe is a machine which capable to produce thin layers of wood called as veneers. Actually furniture makers use it to skive the bark from logs, in order to produce these paper-thin sheets. Veneers are interesting as they can be used to craft patterns of furniture. These patterns will be differentiated to the furniture, making them more appealing and unique. The reason furniture makers can use these veneers on wood is because when they are glued to the wooden surfaces it creates colors and styles, that get us all attention.

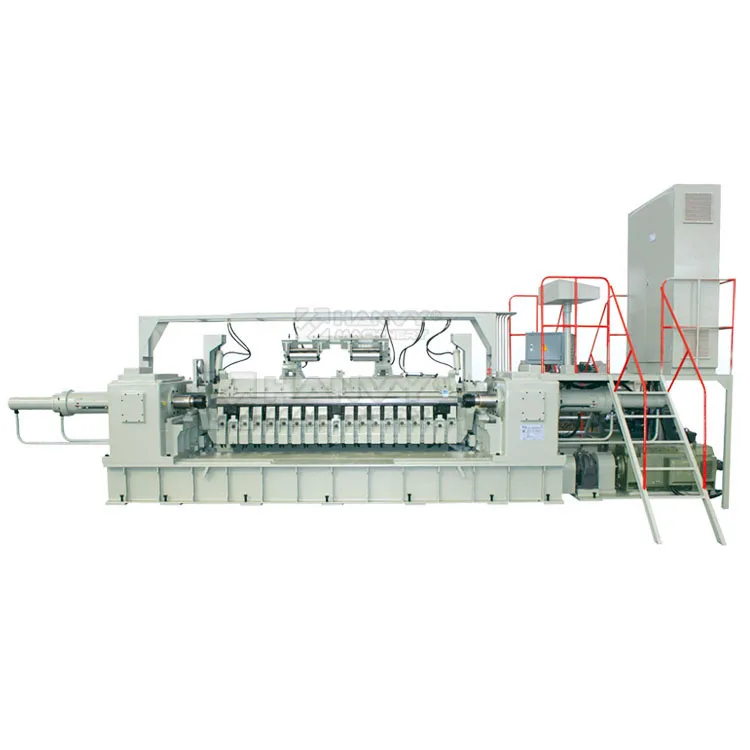

A single spindle veneer peeling lathe is an interesting, but a little bit complex machine; The machine had a really sharp blade and long arm that it used to shave off bark from a log. The log gets injected in the device and becomes an awful roundhgots. By rotating the saw he can slowly whittle away a thin layer of wood on the log. The peeling is carefully done in a manner that would allow the sheet of wood to be finely formed. After the thin sheet is removed, it's cut to size and then applied with glue on a piece of furniture. This is the method used by furniture makers to get handsome, flat faces on their cuts.

Pros of Single Spindle Veneer Peeling LatheSingle spindle veneer peeling lathe is loved by furniture manufacturers for a number places. For starters, it functions to produce thin but strong and flexible wood veneers. This feature also makes it possible to create very detailed and lovely design for furniture. The second is that the machine operates at a far quicker rate than someone operating hand tools, which allows furniture makers to make more pieces from their workshop. This speed and efficiency can be beneficial for scaling a business, as well as keeping up with customers.

Nonetheless, using a single spindle veneer peeling machine also has its downside. The device is also fairly high-cost to acquire, run and maintain. This requires fufture makers to put most of their money upfront. Moreover, its regular operation requires highly skilled operators who are trained to operate it safely and efficiently. Surely they also might make mistakes if unskilled. In the end however, it should be noted this is a machine that only offer you with particular types of wood. However, this limitation can limiting to a variety of veneers that they produce and use in furniture production.

There are certain important tips, which you should follow to make sure that the entire process of using a Single Spindle Veneer Peeling Lathe for this purpose is done in an easy manner. This is one of the big areas where maintaining machine well is very important. Performing regular maintenance will prevent it from accidents and support the device to perform efficiently. And second, operators must be trained properly. That training is essential in insuring that they are using the machine correctly and safely. Finally, every safety recommendation should be observed and the use of security protocols such as gloves or goggles. These precautions help everyone working on the machine stay safe.

Whether or not you can use a single spindle veneer peeling lathe is really going to vary base on your own circumstances. This might be an excellent investment, especially if you are a furniture manufacturer and would like to have very unique patterns on your Furniture. This will enable you execute the designs in your mind. If on the other hand you are just a weekend warrior or do not require that level of perfection in veneer sheets then, maybe something simpler is worth looking into. You should use the tools you feel comfortable with and enjoy working with.