Ever see a plank of wood that's ultra-thin, paper-thin even? They are a wood, however one that is veneer! Veneer becomes so much different things that we can see or use everyday — veneers adorn great furniture, good flooring and even a lot of musical instruments like guitars. However, It needs to be dried before this veneer can be used to create items like the above. And here comes the roller type core veneer dryer to save us.

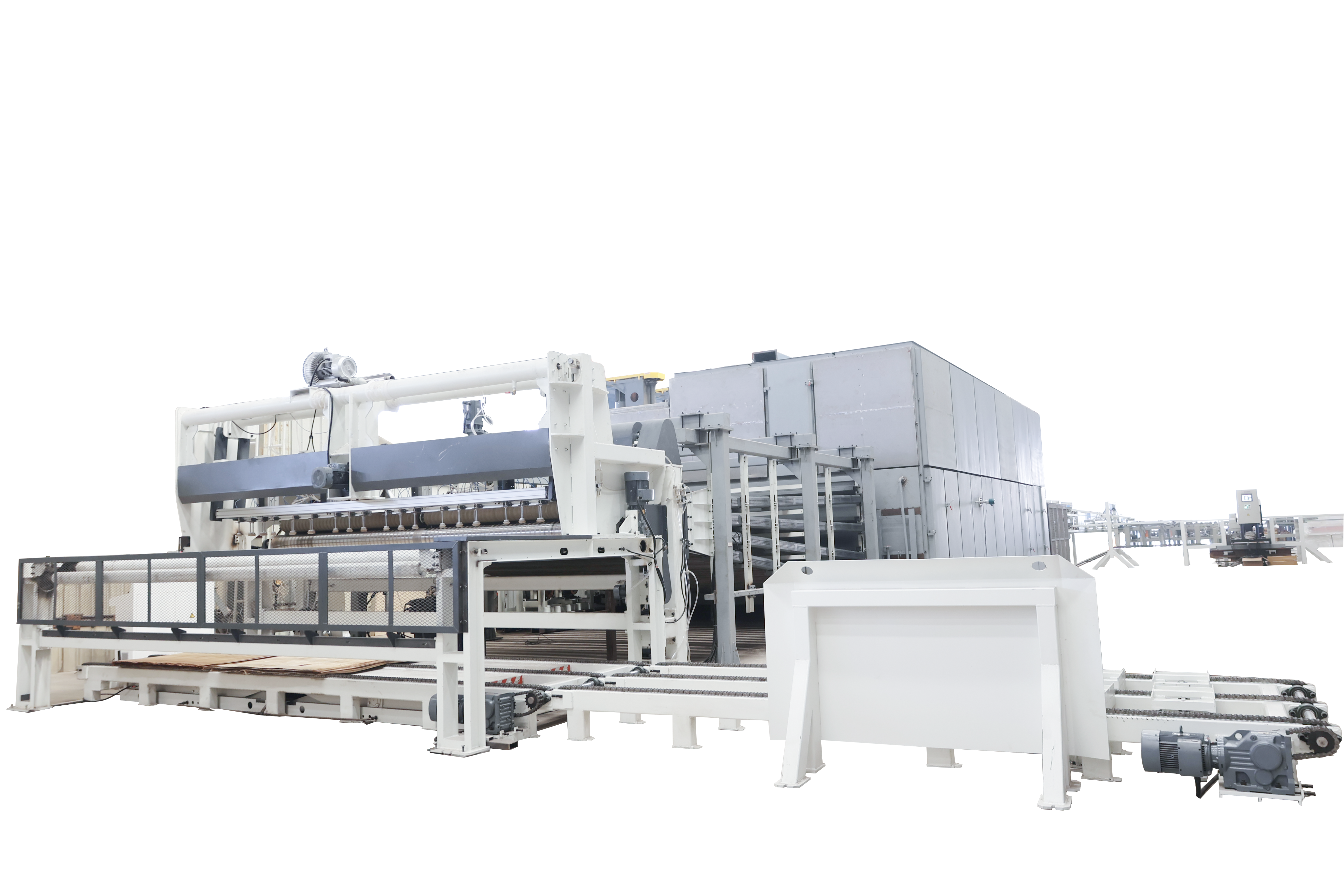

The top roller core veneer dryer is a particularly relevant device that may be of real assistance while drying out your own personal set up and might simply opt this to boost resolve. When it wears out a belt, the wheels get hot and spin. They spin around and they aid in drying your veneer very quickly as well. We actually call this process roller core technology! It ensures that there is no delay to use the veneer.

The roller core veneer dryer is fast and also very beneficial for workers. Workers are able to dry a multitude of pieces of veneer at one time using this incredible machine. This means that furniture makers and flooring companies, as well as manufacturers of guitars etcetera… will be able to make more items in less time for profit! That is to say, they operate faster than others and it helped in meeting customers needs — super important when it comes to products.

A roller core veneer dryer is great as far it helps workers create better items. This special unit, if we dry the veneer, can make it finish glossy and beautiful. Our furniture, floors and guitars will look good with high-quality dry veneer designed to make them strong and non-brittle. They love pretty things and this one helps to make those really easily!

The roller core veneer dryer is also great to use since it saves time, and energy as well. There was a time when guys dried out their own veneers by setting them outside to be cured in the sun. The old way so much time and energy, especially when the sun was not shining. Now with the roller core veneer dryer,veneer drying is become very easy and fast, that way get more efficiency in this progress!

In return, the roller core veneer dryer allows for easier and more precise work. They can control the temperature and speed of those rollers on this state-of-the-art machine. This control is critical to make sure that the veneer comes out dry. If all goes well, everything will have the same thickness and consistency in appearance from piece to piece. Thus making the high quality stuff people would like to use, which is vital.