Ever wondered what the process of making plywood is? Plywood is type of wood that consists thin layers glued together. Plywood is manufactured using a press machine specifically for this purpose. It is quite potent, slamming things together with considerable force. This pressing activates the glues and makes it combine thinly, layer with thicker to create a strong thin veneer sheet.

A press machine is very necessary in the production of plywood it play a great role to keep each layer or sheet from separating and helps convey evenly distributed weight on every part. This bonding gives the plywood a great deal of strength and durability; able to outlast iron without breaking apart. It guarantees a fixed amount of pressure and heat by using the press machine over the very limited time. It is very crucial for this because if the pressure, or heat ain't right enough or just a little more then it should be with lead to maybe incorrect roll over of plywood.

A press machine is useful because it can be used to put more wood together at once. This allows workers to manufacture plywood at a faster rate. A press machine has the ability to apply pressure across all layers of wood rather than one at a time. This is way faster and a big time-saver. Just try gluing each individual layer separately. The press machine is also efficient for the same task.

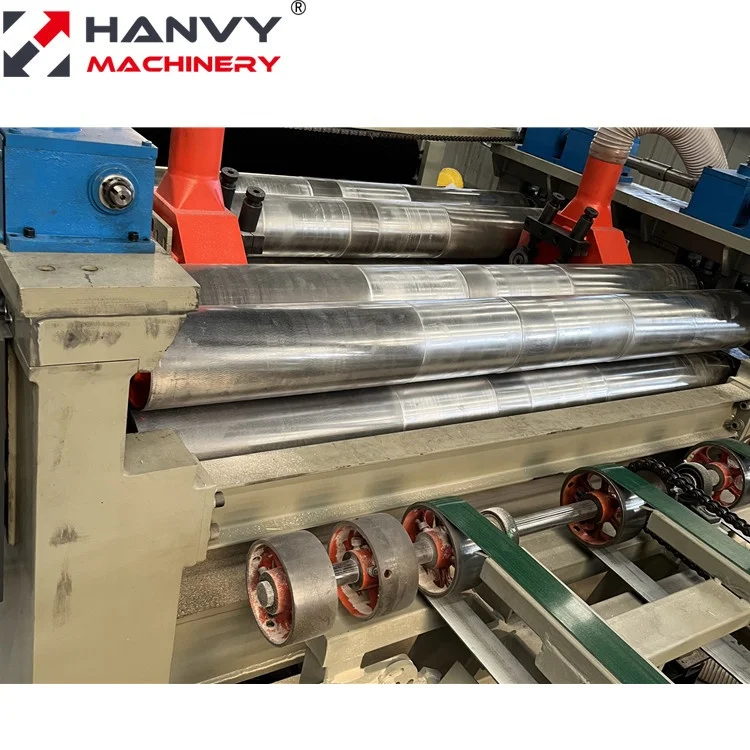

Ideally you want to make the plywood panels with a press machine, these machines can take big sheets of wood and stamp it all out at once. The machine applies even pressure on layers of wood to form durable, flat panels. Some of the uses include: flooring, furniture and wall panels in buildings. Plywood panels are widely used in various sectors because they provide a strong, sturdy and easy to work source. Plywood is a popular building material and it's easy to see why: It's strong yet lightweight, versatile, relatively inexpensive and can be used in almost all types of projects.

This type of machine not only saves your time and energy, but also the composition of plywood. This machine is capable of pressing the larger sheets at once, so it consumes less time and energy. This way, the workers do not have to press each layer separately (which would be 8 x longer). This also allows less use of energy, which is beneficial in terms of being ecological. In addition to that, using the press machine correctly leads to less waste in forming plywood. This in turn results that more of the timber is processed efficiently and less resi due left over, which can not be used.