Do you ever wonder, how plywood is made? Plywood is a type of wood which is manufactured by gluing the thin layers of wood together. The process is crucial for creating very durable and long-lasting plywood. However, plywood will have to undergo a pre pressing session prior for it can be utilized. This process is essential to ensure that the plywood can maintain its strength and use it for various applications.

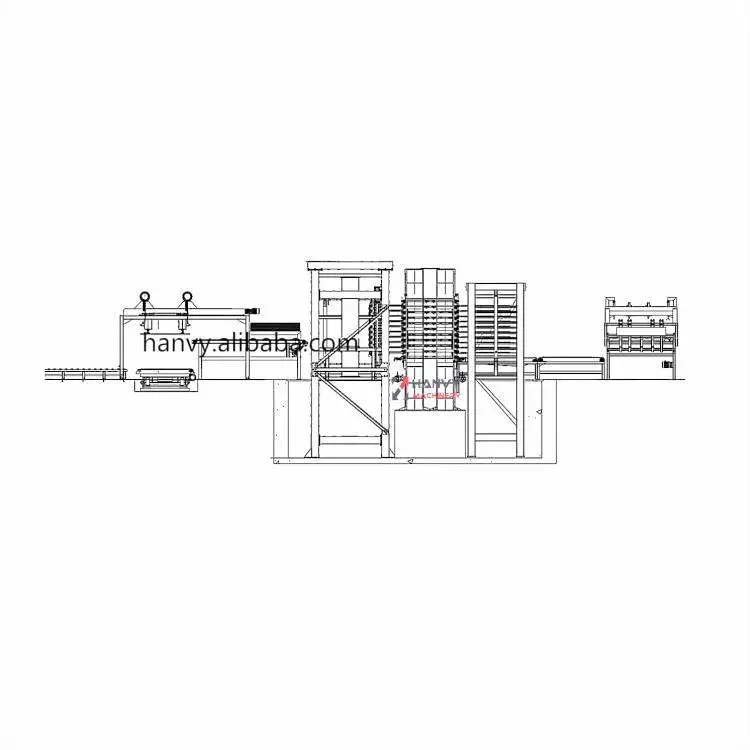

A pre press machine is a type of machinery equipment that assist in the path followed by plywood making, to be more precise it helps you complete this important step. This is done to press together the layers of wood with glue, cure before it dries and be sliced into panels. With the help of pre press machine, you will be able to ensure that no gaps or spaces left between each layer on wood. If it gets into gaps the plywood be much stronger and more stable that is normal means you can use in many different purposes with out breaking or bending easily.

Plywood is commonly used in a lot of places to build houses, for creating furniture and other applications wherever there need be strength from wood. Of course, looks are important too. — Plywood doesn't just have to strong. Better Finish — a higher quality finish on plywood panels makes them look good and they may also fetch more money. Plywood still imposes a noteworthy appearance surcharge on customers.

Pre press machine makes plywood bettererialized When you press each layer of wood together with glue, the process fills in any potential gaps or spaces which will make sure that the end result turns out perfectly flat. The other important aspect of wood is that it is easy to sand and finish, the smooth surface. It also helps the final Plywood panels appear more seamless and clean.

It takes digital time to create a piece of plywood. The individual layers of wood need to then be cored and glued together under high pressure before the plywood can be cut into panels. The process can take quite a while, especially if it is done manually. Doing so in a manual way was not only labor-intensive, it also caused everything else to halt and get backed up when trying to churn plywood out quickly.

Faster and more efficient comes via a plywood pre press machine. It allows us to press multiple layers of wood at once, which is very convenient and saves time. This allows the plywood producers to generate a larger number of panels at brief efforts, which makes it ultimately fruitful and productive system entirely. A pre press machine makes it simpler for the manufacturers to supply their need of plywood and continue with the production work.

The use of pre press machine plays a key role to maintain an accuracy and consistency in producing different types of plywood. It bonds the layers together, in this case for strength and stability. Which translates to the end product will be durable and can stand up for a long time. It also guarantees that the panels are of a uniform thickness so their appearance remains consistent. That common appearance is highly desired for furniture and other decoration uses.