Have you any idea how plywood is manufactured? Plywood is simply a kind of wood which we can use in furniture, home or in any building. Made from thin layers of wood bound together with adhesive, it consists in part. These result in making plywood stronger and lasts longer than traditional wood. Machinery: A plywood machinery supplier is the one who manufactures machines that are used to produce plywoods. These suppliers fill vital roles in the manufacturing process as they provide factories with equipment necessary to produce plywood on a timely and efficient basis.

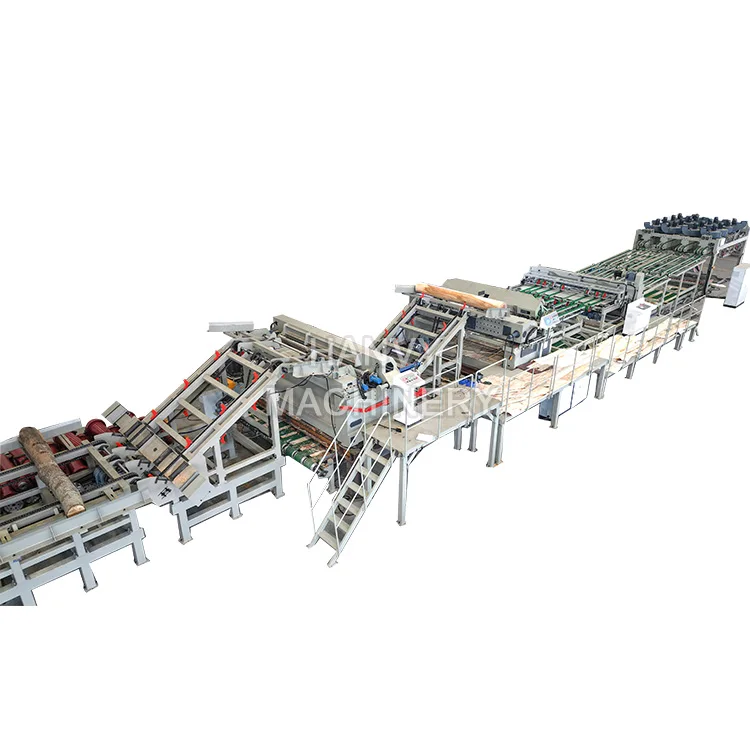

For a better finish and good quality plywood in less time, there are some special machines available with the Plywood machinery suppliers. These machines are advanced technologies that use a precise style of the art machinery. This precision is vital for guaranteeing a perfect bonding of the thin wood layers without any defects or misalignments. A well known plywood machinery supplier will have the highest quality most up to date machines. This ensures that the plywood produced is of a high quality, in order to satisfy many different customers.

A reliable plywood machinery manufacturer is the one who offers machines that are great in performance and last longer. To prevent the problems in production, it is very necessary that the machines are depended. While some suppliers might provide cheaper machines, if those machines need regular repairs they are likely to actually cost over the long term. This is a standard feature in all well made machines. They also include a scheduled service and maintenance of the machines. They help in completing clients projects punctually and within their budget or without any sudden fault by machine.

In Manufacturing the most critical is saving money. They want to optimize their resources and costs as much as possible. Similarly, the best choice for a company may not always be suppliers that offer the lowest prices. A good plywood machinery supplier does not look at the money, it see what he gets in return and acts accordingly. It requires optimal delivered machinery to generate minimal waste and less raw material utilization for its production. This will result in lower production costs overall. A company is considered profitable if it makes more money selling its products than what they cost to produce.

On occasion, folks have to make exceptions for their woodworking jobs. For instance, one machine may be really good for a particular type of task but it might not work so well with another kind of circumstances. A bespoke plywood machinery manufacturer knows it and they have a wide range of various machines. Each of these machine models enables clients to select which is the most appropriate for their particular position and specification in woodworking projects. Options give companies the ability to choose what tools will best enable them for their specific projects.