Plywood is a frequently used building material popular for its incredibly versatile uses. The surface of the engineered wood floor is a gorgeous, real-wood veneer and yet to create it on less-expensive plywood. The result is a tough and robust board capable of being put up in lots of applications. The manufacturing of plywood is carried out with the help of large machines deployed through factories and referred to as plywood machine lines in numerous industries across the globe. In this article, we are going to talk about what the plywood machine lines, why they matter and how it works in order for your production of Plywood is made better.

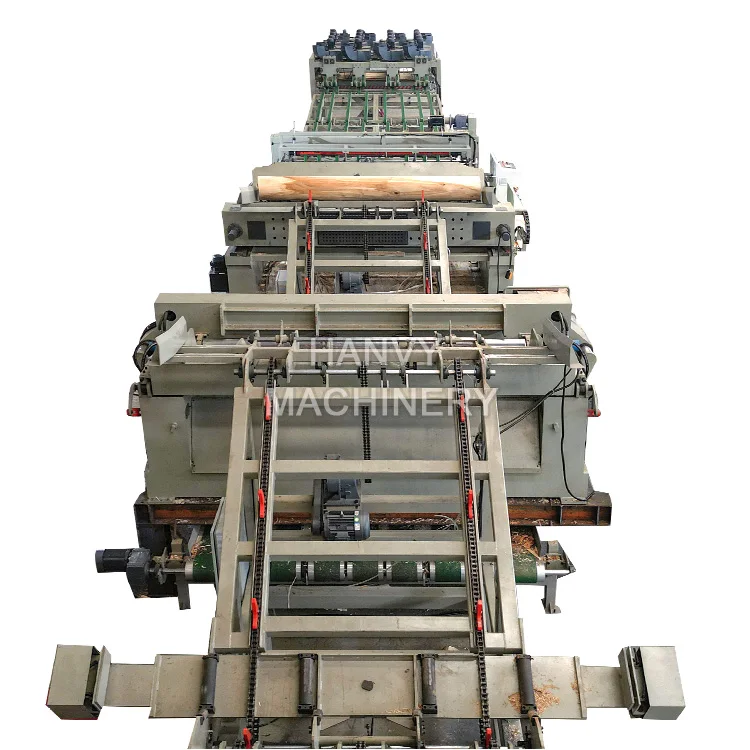

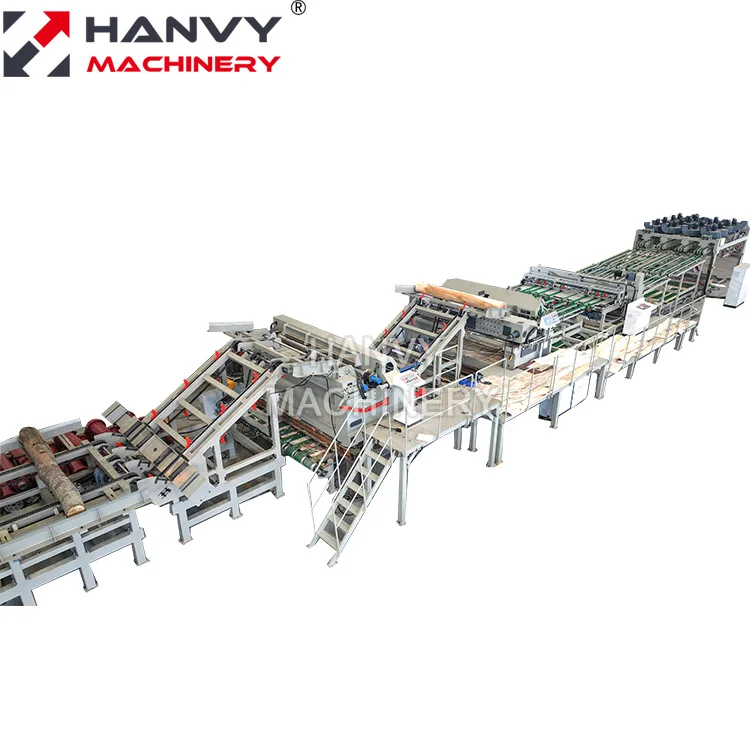

Plywood machine lines refer to the special machines that manufacture copious amounts of plywood boards in a small period. Al these machines possess this particular feature that every piece of plywood is made with the same thickness and size. There are some steps in the production of plywood. The first, bark removed wood is pealed and dried before being glued together into thin layers which are pressed to create a dense board. Plywood factories can fast produce and more accurate using these machines. The end result of this efficiency is saved resources as they can hire fewer workers and produce more plywood without having to stop in between for the machines.

Plywood machine line are heart of manufacturing industry as it provides relevance by which any factory has been able to work more effectively. Its main purpose is to save time and make it simple for getting Plywood on your different needs. The machines are able to make plywood in an assortment of sizes and thicknesses making it easy for factories to have your products tailored. So that kind of ability to really cater specifically to doing things exactly they way your customer wants leads, in general, higher adoption rates and better relationships with the client). As a result, happy customers become added value when they make their next purchase for your business.

In my opinion, one of the biggest benefits that are known to have stemmed from plywood machine lines is cost effective production and I think this too is a thing in its royal name. While functional wood has been around for thousands of years, these machines make it possible to produce great-quality plywood at a much lower price than via other methods. They use less manpower and are able to run through the circuit without any downtime, as well as process plywood faster. Moreover, these machines incorporate latest technology to offer high-quality plywood. This also means fewer resources are spend on the repair of faults and quality control, thereby raising total production rate.

The modern ply machine lines are made to be efficient, robust and accurate as well. They use cutting edge technology enabling them to create an efficient production process throughout the entire manufacturing cycle that keeps their plywood at a consistent quality. They are also designed to be low waste, so they use fewer raw materials in order to make the same amount of plywood. The next major benefit with the plywood machine line in current time is that these are eco-friendly as well. They produce textual products which comply with all sustainability requirements, saving the Earth and continuing to use high quality items.

Every factory is adopting the smart plywood machine lines. In contrast to traditional systems, these new machines can use proprietary sensors as well as sophisticated algorithms that enable them to collect data in real-time during the production process. It enables manufacturers to improve their processes as necessary. Some of the smart plywood machines, for instance, trigger warnings to maintenance staff whenever they seem like feeling gut-sick about other systems in production line. They can also interact with other manufacturing systems to keep the flow of information among them smooth, thereby enhancing overall operation. Smart plywood machine line technology allows factories to increase their productivity levels, minimise wastage and improve the quality of products produced in general.