Then they are chopped down and used in so many things we use every day such as Paper, furniture or buildings Peeling is very important stage of manufacturing any other items from them. Debarking The bark of the tree is stripped away. The bark is the tough outer layer of armor for a tree. The veneer is this beautiful underwood layer and the back side of it, that if we strip off causes reveal what appears to be a fairly uniform wood platform with undulating features throughout.

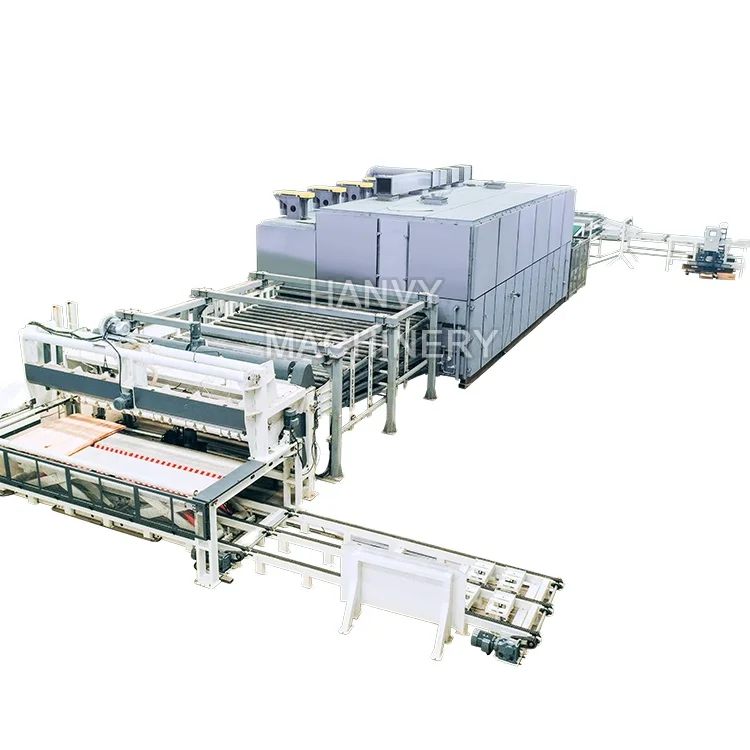

After the tree is peeled and used, it must be properly dried for its wood to behave as you would expect in your furniture or other goods. Well, in enters the peeled veneer dryer machine-a unique kind of a device specially crafted for this work. This machine is designed to run the wood through as fast and effectively dry it so that again we're not bottle neck if we move from one station over another.

This de barker veneer dryer system is a very strong and energy efficient machine. The ingredients of this product are robust and will not decrease with the usage. So it can see day by night. Friends: REACT >_NEXT >> But this is customer-driven development to the extreme in which was created for any kind of bob — they can use without (almost) no problems at all. This is very much necessary in the factories where many people work simultaneously.

Naturally, when creating from wood one of the most important things is homogeneity and smooth finish. Following is what we are talking about, which helps us through the Drying process of our wood on peeled veneer drying machine A slowly heated wood so it can dry like that If its not properly dried out It will bend or damage and Its any construction application value decreases.

The roller used for the removal process is custom designed to crush more wood (drying faster) The wood will dry out more evenly if it has been milled flat vs. round, which is very important step. This process of cut wood in flat condition on one side and conveyorized it to be fed manually fir dryer machine for scuffed veneer. Using warm, dry air blown over the wood by nozzles on a horizontal rotating drum heated by Natural gas. Because of this kind the wood is dried equally and not fry out one part too much which can happen for example with Photomandel diebank.

Also, the following peeled veneer dryer machine can do its job quite well. It is constructed to operate quickly and also completely dry most of wood simultaneously. This efficiency is important because it guarantees that we will always be able to make furniture, paper, and buildings out of wood. A well-oiled machine will keep your production moving within the dependent margins (happily for everyone), otherwise it might be an anchor on which prevents you from delivering goods to customers.

This veneer dryer is "skin peeling type"machine, which has a special feature of drying the wood with most advanced technology. Sensors are placed in the machine to monitor any continuously moisture content of wood. The sensors help the machine to determine exactly when, based on specific conditions of each batch of wood used-is both enough and too much for one load. It is hence necessary to go on guard with respect to the end results.