Plywood is a basic material that we use to make all kinds of practical things. Building houses, furniture are some of the major purposes for which we generally find use in our day to life. Thin pieces of wood, called veneers are used to create plywood. Those veneers have a special glue that makes them stick together very well. Presses like these are used to press the layers of veneers together with just enough force so they stay in place...... A machine is now here to save the day... a hydraulic hot press!!

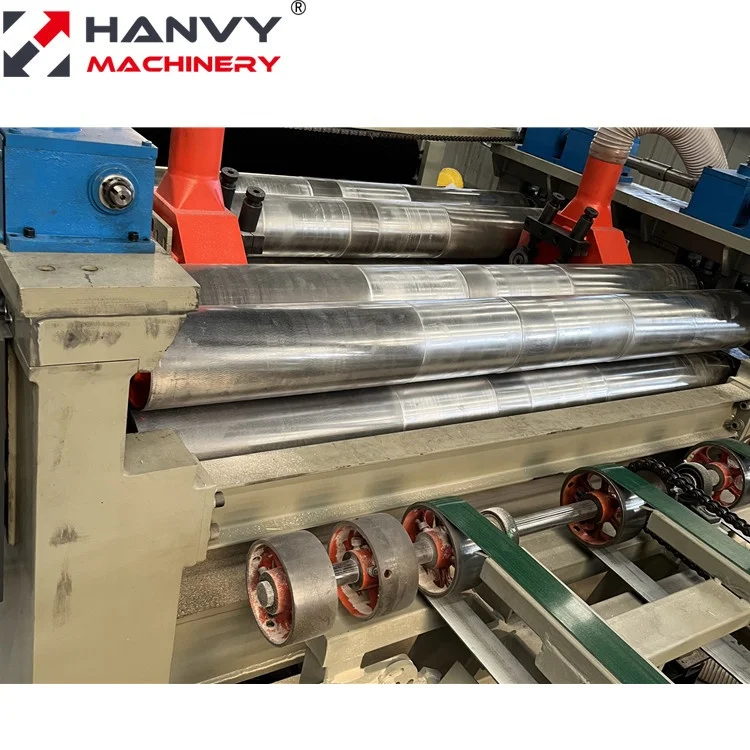

One of the most useful tools is a hydraulic hot press machine which uses pressure and heat to bond wood veneers together into strong plywood. It is a simple and proven method to produce plywood that can be trusted by so many manufacturers. This machine can press multiple layers of veneers simultaneously which saves time and helps in faster production of plywood.

When it comes to hot press machine for plywood, hydraulic makes produce a greater amount of the material than ever before. This machine can press multiple layers of veneers at a time and it is capable to stack them up 6 feet. So that means it can press lots of layers down all at once, rather than one layer at a time. In this way, it speeds up plywood and more no of sheets can be made in just one day.

Hydraulic hot press machines are powered by smart and latest technology to make plywood strong physically. During album building, the machine uses pressure and heat to assist glue that sticks well with veneers. The pressure and heat applied are carefully controlled by computers that see to it the plywood is evenly pressed. The control they take creates plywood sheets that are very durable and can be used for a long time.

It Has Easy-to-Use and Strongness Pressing System:/***/META => 'One of the great features that come with a hydraulic hot press machine is its easy to use & strong pressing system'. Several methods are used to work out what pressure and heat should be applied by the machine (which then can change based on which kind of plywood is being made). It can handle a variety of thicknesses, lengths and widths of veneers which makes it highly flexible. The machine is also friendly configured, to ensure that the labors will be trained and then use it properly for manufacturing plywood of their wish.

This is in fact a modern, hydraulically powered hot press machine that has literally changed the way plywood is now made worldwide. Plywood manufacturers can build strong as well as quality plywood within the prescribed time than ever with this machine. The updated technology itself guarantees that the output was not just powerful, but also endure which is extremely important in making use of on construction and furniture. These features make it the ideal solution for a hands-off, automated plywood manufacturing assembly line capable of flat stacking various range from thin plywoods to robust thick grades.