Plywood is a special type of wood, that we can utilise in variety different ways. Plywood is used widely in furniture making, and also as a construction material for many houses and equivalent buildings, due to its relatively low manufacturing cost. The thing that sets plywood apart is how it is made and the fact that its thin sheets of wood are bonded together to create a durable sheet. One of the appeals to plywood is that it can be cut a million different ways and possibilities. Plywood can also be painted or stained to suit your decor.

Choose the wood: For that you need to select what type of wooden are you going to use for making your plywood, Consider using hardwoods such as birch, oak or maple. This is what gives good quality to the plywood as they are tough and hard wearing.

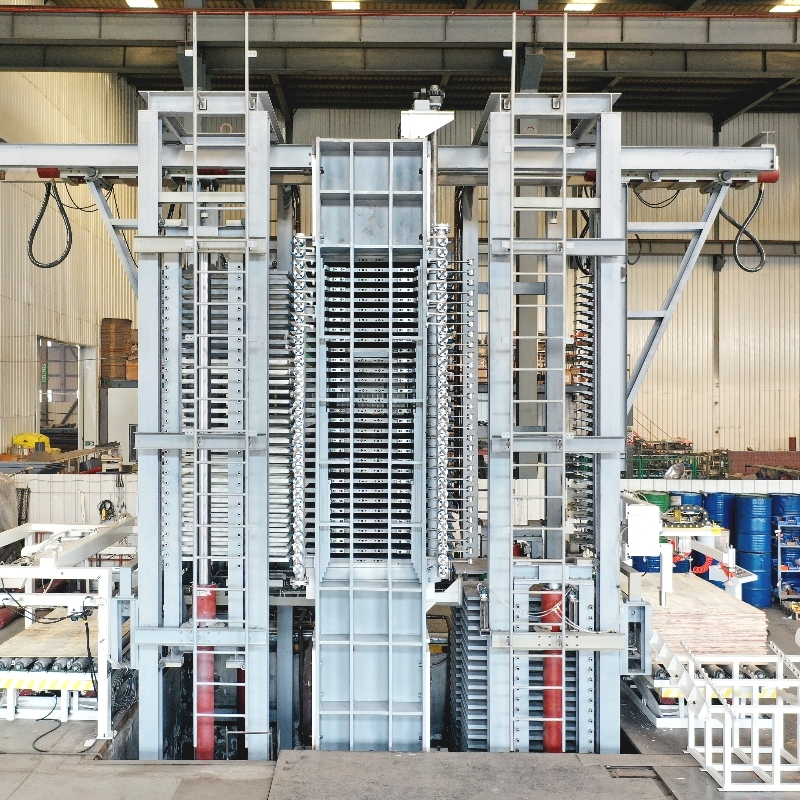

Iron the sheets: After that you stack the glued leaf on another. The layers are stacked up and hot pressed together. The hot press uses heat and pressure to glue all layers together tight. At this point, it is essential for good plywood strength.

Round the corners: The user needs to press this sheet and cool it after which his/her only left with a thing that he/she can trim down. This is performed to ensure that the sides of plywood are smooth and clean. This creates an easier to deal with plywood face for your projects.

The kind of wood you use will make a big difference! The better the quality of wood you use, your plywood will be strong as well. You will use much higher quality hardwoods in making plywood, as it is essential that the wood be strong and durable, but not plentiful.

Choose the correct glue: The right kind of glue you are using plays a significant role as well. This should be bonded with a good quality glue that is also heat and moisture resistant. Doing this will help the plywood last stronger for longer.

Plywood: A sturdy type of timber building material made from multiple layers of thin wood pieces that have been bonded together. The grain of each layer, or veneer is angled in different directions. This particular construction method is what makes plywood incredibly sturdy and flat. More layers means the higher its strength. This is why a lot more builders and woodworkers love to have plywood for his or her jobs.