Favorite thing to watch being made: furniture If yes, then this article is for you. A resource that goes over hot press machines which are vital equipment in the production of plywood furniture. Now I know, this may sound quite boring to some, but believe me, if you happen to be a fan of woodworking (like myself), learning about these has been so much fun.

Plywood is a unique type of wood that makes up some kinds of furniture. Plywood is constructed by placing many thin layers of wood, also known as veneers on top of each other and bonding these under pressure to produce a sheet that makes for strong, durable yet lighter woods. IN the making of plywood - Hot press machine use 'it' a important role in. They bond the layers together quick and dirty style.

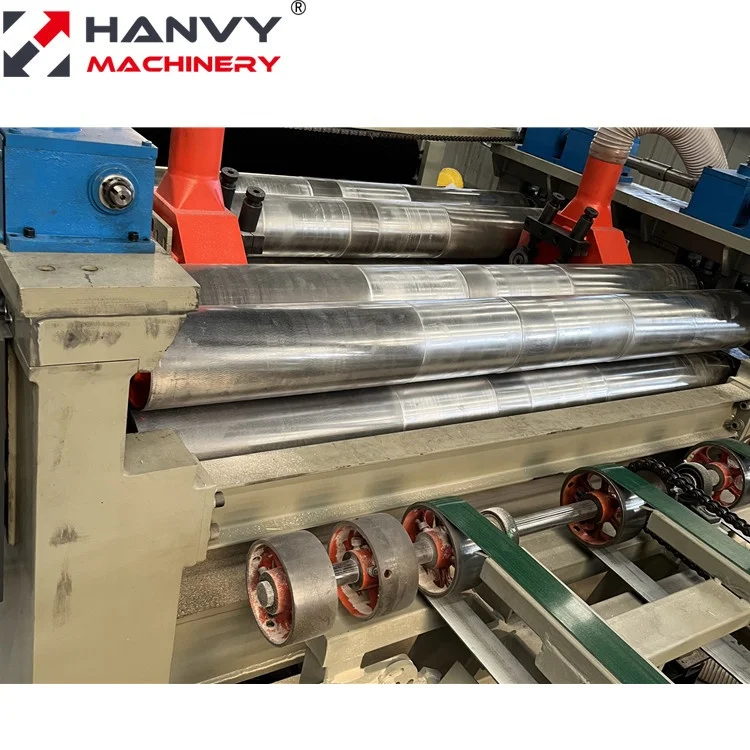

If you still remember, hot press machine would be familiar to all of us. Yes, it's simply a way of using heat and pressure to "glue" the layers of wood_up. This machine heats similarly and compresses the cellulose in wood at once. This heat and pressure combination increases the glue stickiness. The glue will be completely dried within only a couple of minutes. Then, the plywood can be moulded and cut into various furniture like tables, chairs etc.

Manual production of plywood is very time-consuming and forces large roughnesses in to surfaces. At tines, the furniture may not be durable enough to withstand everyday use. But when we do this furniture with hot press machine, the furniture is smooth and very strong to use in everyday life.

The hot press machines are made in such a way so as to produce even heat and pressure at all the layers because that is exactly what you need for making strong wood which has no void spaces. In this way, ensures a proper distribution of the adhesive so that it can adhere reliably to all layers. Therefore, you received a high-quality plywood that is durable and look presentable.

The hot press machine is high efficiency. In only a matter of minutes, it is able to accomplish quite a bit mainly because this makes woodworkers crank out home furnishings in decreased cycle time. Only a few people are needed to operate the machine, which reduces labor costs. In addition, woodworkers be capable of save more cash, that may merely translate to increased profits with regard who are suffering business.

A great hot press machine goes one step further providing you with the ability to control heat and apply pressure automatically so that when wood veneer is placed in between them, it has a correct amount of heat & pressure. This takes out all the hard work which means you do not have to complete it manually. The machine is doing the work for you! It is also able to make several types and sizes of plywood, including certain varieties of water-resistant general purpose plywood. This in turn will give you an opportunity to grow by including wood furniture for bathroom & kitchen cabinets, flooring and more.