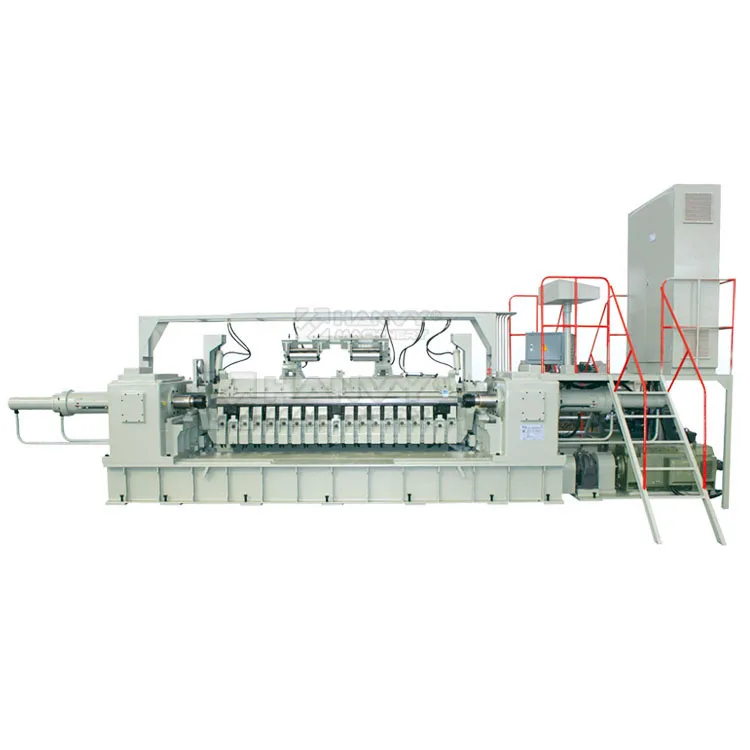

Do you like wooden furniture? But do you ever wonder, how was it made? We all have wooden furniture at home. Peeling Veneer :- Peeling of veneers is one amongst the foremost vital method as a result of it decided not simply quality however conjointly the planning on completion. Veneer is the thin layer that which once removed from logs. Although this layer is very thin, the task of giving furniture a beautiful appearance depends on such an imitation! Veneer is peeled by machines known as veneer peelers. One such new method is double spindle veneer peeling and it has certain advantages in the process.

You need good quality veneer for peeling so nice furniture is made that people love. This is a mirror finish and high gloss you do not get only with veneer. The double spindle veneer peeling has been improved, the two knives in it could peel the wood opposite to each other at one time; This makes the machine able to handle the log better, and so making fewer mistakes while peeling. Because of this, the fewer mistakes made at production-level veneering create a gluer desking with little variance in thickness and less waste than saw & slicer. This is very important since reduced waste = less resources used.

This also leads to the double spindle veneer peeling keeping more work within less time. Productivity - Just productive is a word that means can do some work in scheduled time. The old machines are replaced with double spindle veneer peelers, where a larger amount of veneer can be peeled faster. As an example, one double spindle veneer peeler can replace two traditional peelers. This will result in faster veneer production for many companies that cut trees to make wooden furniture. They are working faster to fill the growing consumer demands and not producing so that they can work better.

Source: Companies who are in the business of Manufacture and Sale Of Wood Furniture would like to reduce costs while making good products. They need to figure out a way to deliver the same great services at prices that remain low so there is not large sacrifice in quality. AdvantagesThis combination for double spindle veneer peeling has some special reasons, one of those is that it saves machine numbers and manual requirements to do such works also this technique minimizes wastage in the processing. In addition, double spindle machine has strong persistence can work long hours without stopping. As a result, the production is stable and calls for less maintenance which lets workers concentrate on other key elements of flowchart processes.

When it comes to veneer is the ability to peal it so that it is as exact and uniform in width throughout your project. Precision and Consistency are Precision means very accurate the works do in proper manner every time. Because a double spindle machine peels the veneer exactly evenly on both now resawingDouble-spindle machines are very precise, so there is also no room for shaving.squeezeidentical sides of the trunk. The thickness uniformity is extremely important to make good furniture from veneer. Also, as they are run by computers; these machines keep providing you with even results every time. This unalterable setting ensures a high-quality veneer that complies with the same standards of quality, no matter who is operating.