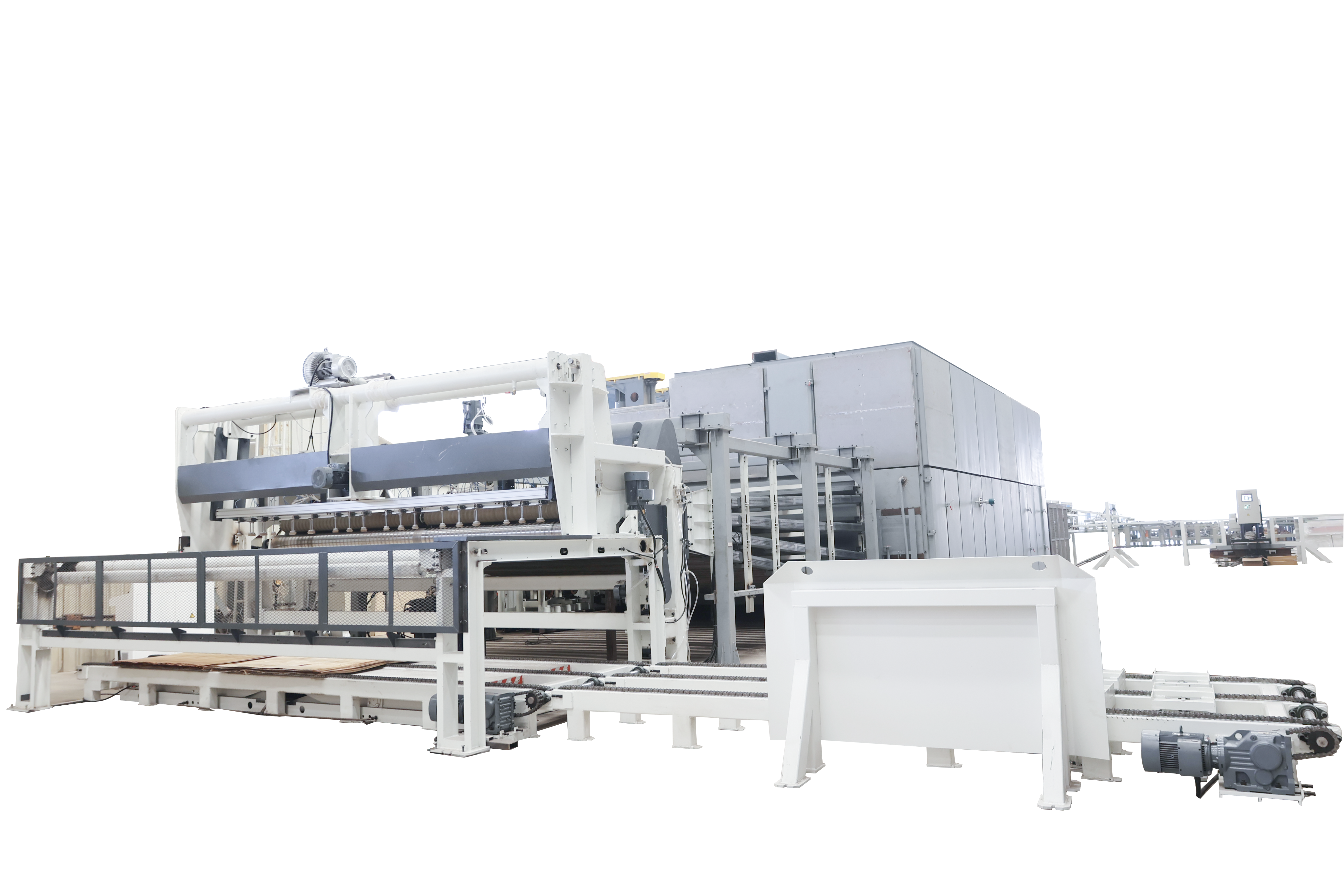

So what is a core veneer dryer? A gastly important mega-machine, which dries thin wood slabs of woods called veneers. They are quite practical in many things you use every day - everything from furniture to homes, and even bridges... is made with something called plywood which has veneers as layers. But not every drier can do this trick, it will need very complex technology in order to dry properly and quickly.

For plywood production, it is of paramount importance for the core veneer sheets to be dried as quickly and safely for them. This Is where the core veneer dryer is useful Hot air is used to assist the evaporation of some moisture from the veneer reusepractical [via instructables! These veneers become loose and they can be glued together to form strong, rigid sheets of plywood. Poorly dried veneers may not provide enough strength and durability to stand up to the many uses of plywood.

Good quality plywood requires better controlled drying of the veneers as to temperature, but also by mosture content. Core veneer dryer does an excellent job at this, as it can control the temperature and humidity to a T which allows us to manufacture high quality veneers. The accuracy is of great importance because while drying if the veneers are not dried fine, they might become weak or can warp which in turn would affect the plywood quality.

Owning a plywood factory is not only to produce products, but also for operation and profit. That importance offers explanation for the existence of the core veneer dryer. It aids in expediting the drying procedure that makes it faster and more reliable. The factory is able to produce more plywood in a shorter time period because this machine does its job so well. This increase productivity can translate into higher gains for all the players in plywood production.

A fast drying process not only makes good business sense; it is also environmentally-friendly. The also take with high efficiency energy saving garbage, waste of most modern core veneer dryer. These machines are capable by recycling hot air and can intelligently control drying prices through sensor systems, making them use energy better. So, it can take place in a relatively inexpensive and eco-friendly process that bodes well for our planet earth future.