Do you manufacture furniture or build houses and need to dry the veneer thinner wafer sheets? Did you say yes, then a veneer roller dryer machine is definitely something that should be on your mind. Especially designed for enhancing speed drying of veneer sheets. This makes it the ideal system to ensure you are always close enough to your ready-to-use sheets for all building works, or furniture production. Therefore, follow these five reasons to know why roller dryer machines are considered as an ideal choice for your work on the veneer.

In the ‘olden days', it sometimes would take veneer sheets a long time to be dried. Traditional style page flipping and airdrying pages. It is a very difficult and laborious process. Veneer roller dryer machine eliminate the slow drying process! That machine can dry more sheets in one go, that it spreads down your time rather with a less use of manpower and leads you to save Labrador costs at the end. This means less waiting and more work on your projects.

If you are using a roller dryer machine, perhaps your veneer sheets would be better off ever than they were. They distribute the heat and air across all of your sheets, which is why it's like this. The sheets dry evenly with the same amount of even much heat and air so they have equal levels of dampness. This matters because it drys all the pages at the same time, which means that your whole stack of paper is just as (or un-) good for quality and longevity. Improved quality of veneer sheets to enrich furnishings or construction business!

This article will help you decide between a pin marking machine and veneer roller dryer if you are unable to determine which of the two is ideal for your situation. This machine does much of the heavy lifting for you and frees up room so that you can get on with other key elements in your process. This way, you can concentrate more on the other verticals in your work and less flipping sheets and waiting for them to dry. It is also cost-effective since machine introduction into your current product line can be done quickly and easily.

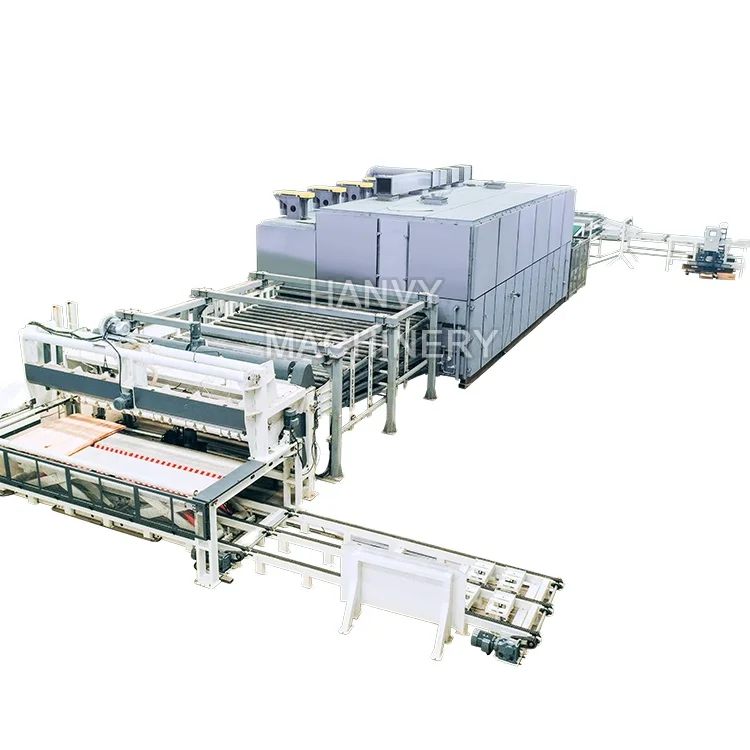

Here are our veneer roller dryer machine. Responsible In offering, the advantages of performance at its top e is automatically temperature control to help maintain sheets' ideal warmth during drying. Veneer sheets will lose their properties if you do not maintain them at a certain degree of temperature. But — if you let them over-bake during this drying process, and experience cracking or warping later on (and why would they do that?), then it likely means your paper was too thirsty to start with … so put the damper back into damp before collage!

Reliability and Durability: This is one of the important features that you should keep in consideration when finding a machne. Features:- We manufacture our veneer dryer machine, which last longer similar to all other timber products. The materials used on it are heavy duty and, therefore, will not fall apart after a couple of hours spent working in the kitchen. This means you are getting your veneer made to be the most reliable, durable and effective it can possibly be everyday. Buying this machine means that you can sleep assured knowing it is a solid investment in your company.