Plywood is a type of wood that consistof several thin layers —also known as veneers—. The layers are bonded to produce a strong, tough composite. Plywood finds its usage in a number of areas from building houses, to furniture making and even flooring for homes and offices. These are tools specially made as Plywood Manufacturing Machines that assist the process of making plywood.

At construction sites, Plywood Manufacturing Machines are incredibly useful due to its numerous advantages. They are the invention of fire laminators that greatly reduce plywood manufacturing cost and time versus a manual process done by hand. These machines save the workers from manually lifting heavy boards or wasting hours on cutting and shaping wood. This makes the job of workers in plywood manufacturing factories less tiring and more efficient.

Making plywood was a tedious process before the invention of Plywood Manufacturing Machines. Each layer of wood had to be cut perfectly and assembled by hand, hence it was a long process. This old school way demanded a ton of effort and it was very much prone to errors as well leading to uneven output. Today, plywood is then made much more fast and easily thanks to this machinery. That is why there are now many factories around the world that produce this important material and wood presses for veneer& plywood manufacture have changed significantly, because once again thanks to innovative technology.

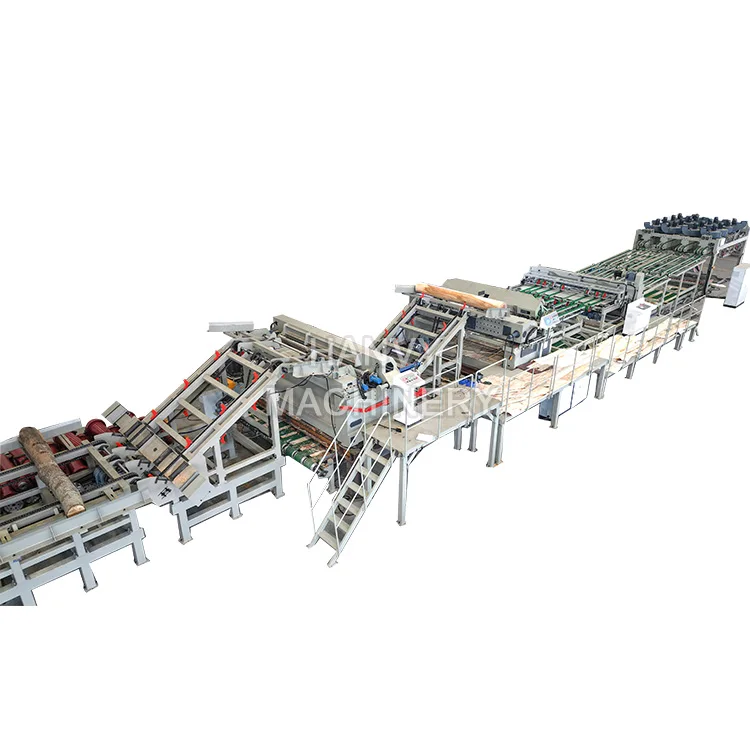

These Plywood Manufacturing Machines are also featured with a number of amazing characteristics that put them in the category of an enhanced working ability. Specific belt saws actually have high-tech blades specifically designed to precision-cut the wood into pieces of just the right size. Moreover, it is equipped with rollers facilitating entry of wood inside the machine. As well as this, sensors are another key feature built into the machines. Both of these sensors aid in the operation and minimization of errors by machine. To produce plywood without these advanced traits would be far more difficult.

Employing Plywood Manufacturing Machines can really be a cost-effective method for most companies. They are constructed to manufacture the plywood at a faster rate than manual ways. With all this increased production, companies can sell more plywood and therefore make a profit. This is really good for the business to get succeed and expand in that marketplace. Using these machines businesses are also able to save in terms of labor costs since lower number or workers is needed for the operation as against hand production.

One of the major benefits of using Plywood Manufacturing Machines is that they make sure ton provide very high-quality plywood. It means that all the plys appear and feel to be of an identical grade, which is good for a customer. If companies are able to consistently prepare plywood that is of one standard quality, it would be easier for them to sell their products. Consistent quality assures customers what they will get when buying plywood, and to a customer this is huge.