There, have you used plywood before? If you are already, I am sure that your next thought is just how to cut it. Plywood is a wood made up of thin layers and depending on the project you are going to build, having an exact size will be necessary. Thankfully, there is a way to do this that involves a special tool. This new tool is named a plywood double sizer and will save you some trouble.

A plywood double sizer is a tool that allows workers who handle wood to accurately and efficiently work with cutting pieces of material known as plywoods. This machine is built with two kind of blade which function in combination to cut the size you want for plywood. If you have a plywood double sizer, it guarantees your cut is straight and exactly the same size of any piece that came before or after it. That is very good for the contemporary age but if it means that your pieces will potentially end up different sizes, knowing may be pretty important since how to put a project together would typically depend on their being in certain size ranges.

A plywood double sizer makes it look like a woodworker has been doing more than 24 hours of work in just one full day. A big honkin' machine that will slice through 4x8 sheet goods at warp speed with surgical precision compared to doing it mano-a-mano. This enables you to complete your projects faster when you can quickly cut up more pieces of plywood. This is a great advantage, especially when you are dealing with large-scale workloads or have thousands of orders to process. At the end, this can help you make more money as it will enable you to handle higher workload by doing same amount of task faster.

Another thing that is so great about a plywood double sizer, it can be adjusted to conform to the demands of various kinds of woodworkers. That means you can modify it for your projects or preferences. For instance; some machines are made to handle a variety of blades so that the plywood can be cut at different angles depending on what you need it for. This is great because not all projects require identical cuts.

Some machines let you switch how quickly they cut, just as well blade choices. That way, you could maintain more exact cuts by adjusting the speed. Woodworkers can achieve specific results in their own projects, thanks to the ability of customizing a machine according to his/her need. If you have to do a lot of cutting and need faster cuts or if there are many angles that must be precise, then the answer is probably yes on getting a CNC plywood double sizer.

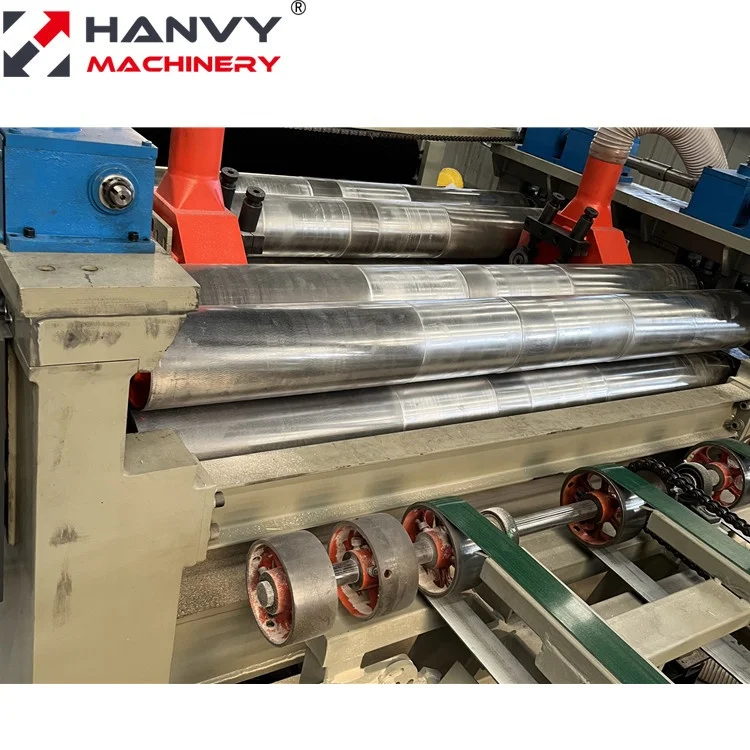

The materials like in thing that made the plywood double sizer it usually of hard & strong type material such as steel, aluminum etc. This robust build helps ensure the machines can take a lot of use and abuse without breaking down. This machine will be sure to last through years of demanding jobs, like cutting a lot of plywood which can put quite the wear and tear on equipment. A plywood double sizer is a solid investment for those who rely on their precision wood cutting tools to match the pace of your work.

While you may be a bit concerned about the investment, as it can facilitate tyou o produce more dowel-sized material in less time. Just remember, these machines can save a lot of time and get things done faster. Things are looking up just as you get to the Eco-30 mode that dries a full load using 50 liters of water - more than most other machines use in standard modes. If you consider how much more productive your can become, easily the investment is worth it.